Project Details

Location

Sydney CBD, NSW

Industry

Automative Technology

Size

1900m2

Value

$210k

Designer

DY Constructions Australia

Duration

6 weeks

Delivery Method

Lump Sum

- Mezzanine floor construction with stair access

- Ceiling height adjustments to meet compliance

- High bay LED lighting relocation and installation

- NBN Cat 6 cabling throughout mezzanine and warehouse

- 3-phase power circuit installation

- Mezzanine pallet gate and balustrading

- Emergency lighting, nosings, and tactile indicators

- Structural engineering certification provided

Project overview

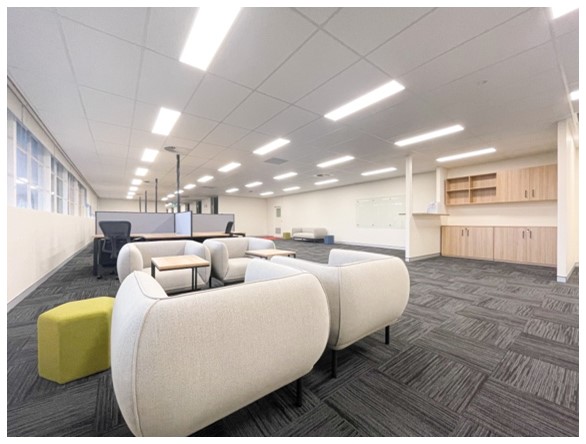

Warehouse office fitout completed for Garrett Motion in Gregory Hills, including mezzanine works, electrical upgrades and NBN data cabling.

Client Brief

Garrett Motion, a global automotive technology company, engaged DY Constructions Australia to help expand their warehousing capabilities in Gregory Hills. The client’s brief was to increase storage capacity and support business growth through the construction of a structural mezzanine floor. DY was also required to coordinate with the client’s racking suppliers to ensure the new layout supported efficient workflow and compliance.

Challenges

The project presented several regulatory and compliance complexities that required careful coordination. DY Constructions was required to obtain council approval and ensure all works met BCA compliance standards.

The introduction of the mezzanine increased the building’s floor capacity, triggering a change in building classification and the need for essential services upgrades. This included coordination of fire safety and mechanical system enhancements. Additionally, DY engaged a structural engineer to certify the mezzanine and ensure all design elements aligned with Australian standards.

The Solution

To meet all regulatory requirements, DY worked closely with a private certifier and structural engineer to ensure the mezzanine was fully compliant and certified. The team managed council approvals, coordinated essential fire and mechanical upgrades, and adjusted the design to suit the new building classification. All works were carefully planned and executed to meet safety standards and support the client’s operational goals.

The Result

All works were completed in line with BCA and council requirements, with final inspections passed and the Occupation Certificate (OC) successfully obtained. The upgraded warehouse now features a compliant mezzanine structure, essential services upgrades, and a layout ready for racking installation. The client was highly satisfied with the outcome and the building is now equipped to support their next phase of growth.