Project Details

Location

St Leonards, Lower North Shore, NSW

Industry

Dental and Healthcare

Size

150m2

Value

$170k

Designer

DY Constructions Australia

Duration

xxx weeks

Delivery Method

Lump Sum

Completion

2025

- Custom lab joinery and benchtops

- Full-height plasterboard partitions

- Installation of pigeonhole cabinetry

- Power and data tie cabling

- Fibre optic cabling and patch panels

- Plumbing works for air line to lab room

- New vinyl flooring and surface protection

- Electrical and lighting upgrades

- Furniture and table modifications

- Works delivered in a live office environment

Project overview

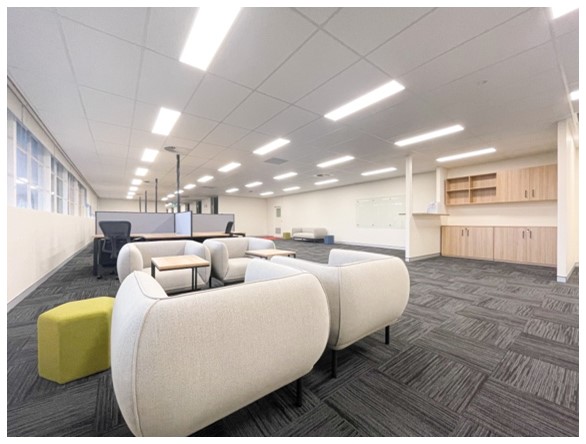

Office Fitout project for the Australian Dental Association’s St Leonards Office.

Client Brief

ProGroup Management engaged DY Constructions Australia to elevate the quality and functionality of their office environment and accommodate a growing team. The client sought a modern, well-planned fitout that would maximise workspace efficiency while enhancing overall presentation.

DY delivered a full-scope solution across two levels, including new office partitions, custom joinery, acoustic upgrades, flooring, furniture, lighting, and services. The works were tailored to support both day-to-day operations and future expansion.

Challenges

The client initially provided a floorplan that did not meet BCA and accessibility requirements, requiring DY to redesign the layout to ensure full compliance. As part of the brief to expand the office, the client also requested that the workspace extend into the existing warehouse—a complex adjustment that required careful consideration of mechanical systems and building code constraints.

Additionally, the client aimed to maximise workstation capacity within a limited footprint. DY had to carefully plan and adjust workstation placement to achieve optimal density without compromising usability or compliance, accommodating several design changes throughout the process.

The Solution

DY collaborated closely with a private certifier to review the client’s initial drawings, making iterative adjustments until the layout achieved full compliance and met the client’s functional needs. This ensured the final plan was both regulation-compliant and aligned with the intended use of the space.

For the office extension into the warehouse, DY coordinated layout modifications and installed a new air conditioning system to service the expanded area, ensuring the build met mechanical and BCA requirements. To address space constraints, DY carefully planned the workstation layout to maximise capacity without compromising movement, comfort, or compliance—successfully delivering a design that met the brief.

The Result

The project was completed to the client’s satisfaction, with DY securing the Occupation Certificate in time for ProGroup Management’s planned move-in. The final scope included full office partitioning, custom joinery, acoustic panels, flooring, lighting, electrical and data works, workstation installation, and new air conditioning for the expanded office area—delivered as a complete, compliant fitout solution.